| |

Bitmapping a cylinder end

At

times the need arises for a circular bitmap to be placed

on the end of a cylindrical object and the process tends

to give some Swifters a lot of grief.

In much the same way as bitmaps are placed on square

extrusions, the same is true for round extrusions. Most

commonly the objects are dials, guages or watch/clock

faces. This tutorial is mainly focused on correctly

aligning the bitmap on the material.

If you want to place a bitmap texture on the end of

a cylinder, use this technique and place the extrusion

as a cap on the end of the cylinder. At

times the need arises for a circular bitmap to be placed

on the end of a cylindrical object and the process tends

to give some Swifters a lot of grief.

In much the same way as bitmaps are placed on square

extrusions, the same is true for round extrusions. Most

commonly the objects are dials, guages or watch/clock

faces. This tutorial is mainly focused on correctly

aligning the bitmap on the material.

If you want to place a bitmap texture on the end of

a cylinder, use this technique and place the extrusion

as a cap on the end of the cylinder.

So how do we do it? |

Step

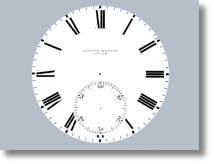

1 - The bitmap

|

|

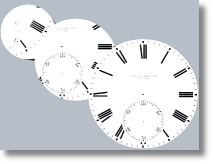

When

using the bitmap of your choice it actually does become

a case of "size matters". The larger the image

and higher the resolution - the better the finish when

rendering. However if the image area is small within

the render, there's no point using large files for,

say, a tiny speed guage on a motorcycle.

The

image on the left is 345x345 px in size and can be downloaded

here.

|

Step

2 - Creating the material

|

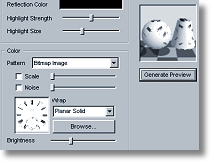

|

Go

to - Setup > Materials.

Highlight "Bitmap" from

the list and select "Add Material...".

Give your new bitmap texture a Name (e.g. 'watchface'

). In the Finish sub-panel, open the

Ambient Color picker - select white.

In the Color sub-panel, select "Bitmap

Image" from the Pattern drop down

menu. When prompted to select a file - select the watchface.bmp

file. Leave all other settings at their default values!

You

can view the full panel image with all settings required  . .

Hit

"OK" and "Done"

respectively.

|

Step

3 - Creating the object

|

|

Creating

the object is very simple. One of the improvements of

Version 3 over Version 2 was the inclusion of a selection

of preset shapes in the extrusion editor. By making

use of the preset round extrusion it will speed up the

process of creating our perfect circular object without

the annoyance of all that hit and miss guess work to

get the shape correct. Press the button in the extrusion

editor for 'round extrusion' to create the cylinder. |

Step

4 - Applying and aligning the material

|

|

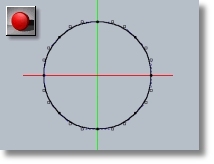

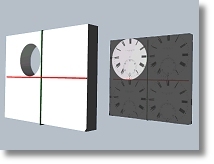

To

understand the way bitmaps are placed onto the surface

of extruded objects in Swift3D, I have created an illustration

on the left of the extrusion editor environment to graphically

help the explanation. The rear object represents the

extrusion editor work area. As seen in the image, this

is how the extrusion editor tiles the bitmap. Placing

an extrusion's centre at 0,0 will make the bitmap seem

to tile. You probably have discovered this already,

rendering after placing a bitmap on an extrusion only

to find the image ending up like a messed up jigsaw

puzzle. |

|

|

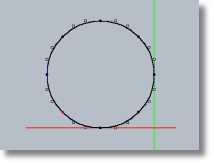

The front object represents the circle you just created

in the extrusion editor. By remaining in the extrusion

editor and moving the extrusion so it is placed over

the bitmap in one of the four quadrants with its 2 edges

touching the axis lines will produce a correctly aligned

bitmap finish. |

|

|

I chose to move the extrusion left and up as seen

here, so now the extrusion has the bitmap correctly

aligned to it.

Do

not move the extruded object in the main editor to

try and align the bitmap. It simply will not work

that way. It has to be adjusted in the extrusion editor.

|

Step

5 - Sizing to fit

|

|

Go

back to the main editor.

"Hang

on!" I hear you say as you have

eagery hit the quick render button to see how successful

you were - "I have nothing like a

great finish!"

What

you should have is the image shown here. This is because

the bitmap image is too large for the object. To get

it to fit the bitmap you must increase the size of

the extrusion.

|

|

|

Shown

here are the results of progressively increasing the

size of the extrusion using the Sizing option

from the Properties Menu. The largest

extrusion was the result of increasing the size of the

extrusion by two. It is just fortunate for me that for

this particular project it was exactly the right increase

in size to fit the bitmap! So when sizing up it is a

stepped process of increasing size - checking the fit

and repeating until the extrusion is large enough. |

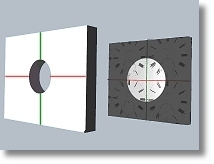

Step

6 - Completing the scene

|

|

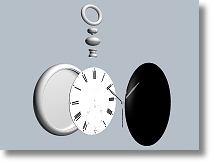

To

complete the scene and put the bitmapped extrusion to

work, I created the watch backing, the glass face, the

winder, and the bottom connector in the lathe editor.

Then they were scaled to fit. The silver knurls on the

winder were a copy and paste of the winder and then

its sweep angle reduced to 5%. I then copy/pasted it

several times around the edge of the winder. The watch

hands were created in the extrusion editor and sized

to fit. The egg shaped sphere was a default sphere with

its height reduced. The torus was also a default torus

with its width widened a little. They were then scaled

to fit. |

Step

7 - Final adjustments and rendering

|

|

The

final adjustments applied to the image were a default

chrome finish to all the silver parts. A default gloss

black to the hands. A default glass finish to the

glass face. A default gold finish to the winder. I

then reduced the 2 default lights to a grey from the

default white and shuffled them around until the lighting

looked better from the camera angle I was using. I

placed the default grey ripple gradient environment

into the scene. To finish I placed another target

light to illuminate the watch face.

|

|

|